Today’s DIY: How to solder copper links with beads

If you like bead-embellished wire links, but wire wrapping is not your forte, then this is an excellent project for you!

See previous blog post for basic soldering instructions, including links to torches, soldering surfaces, basic tools and setup.

- When cutting or soldering, wear eye protection to protect your eyes from flying bits of wire or solder.

- Make a few coils: as many as you can comfortably fit on your ring-bending pliers, a suitable size of Wubbers bail-making pliers, or the fun new shapes of Wubbers mandrel pliers. For round links, I prefer ring-bending pliers for 20-22mm loops (3/4″ – 7/8″), and the X-Large bail-making pliers for 12mm and 15mm links.

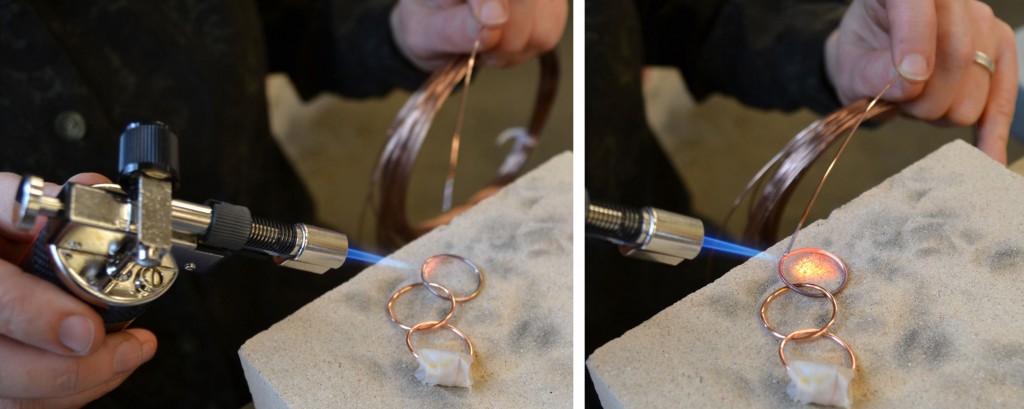

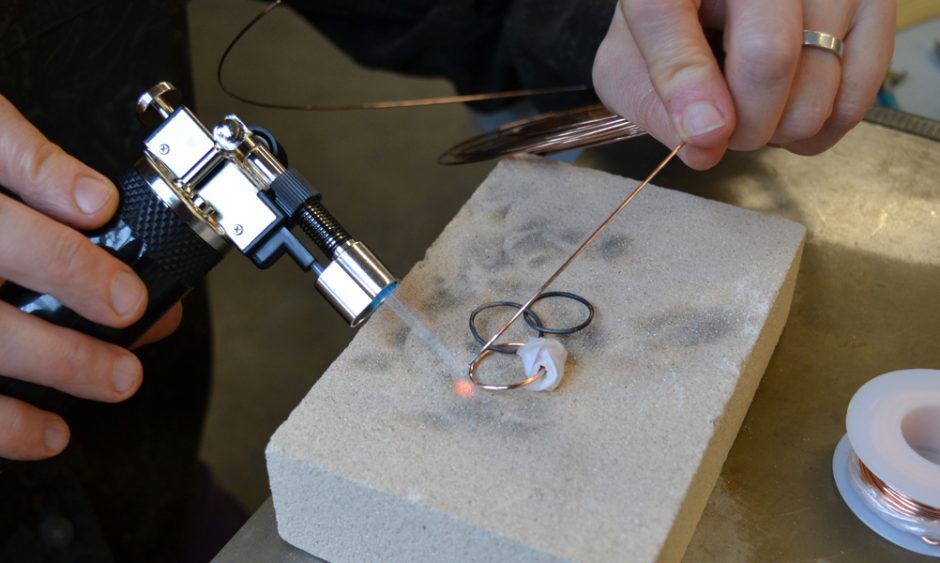

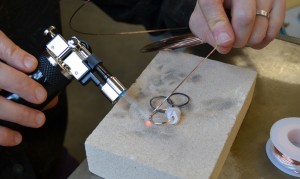

The link on the left, is very badly aligned. It won’t solder at all. The link currently being soldered worked ok, but for a really professional join, you should not be able to see the opening that clearly. The left-most black link did not fully solder, because I didn’t notice I had too much of a gap. Sometimes this happens when I talk and demo!

You can line up a few links, and solder them one after another, then use fiber-grip steel tweezers to pick them up so you can quench the heat in a cup of cool water.

Link 1. (Click image to zoom.) When soldering each link, be careful to keep the paper and any previously-soldered links at the far side of the current link, away from the torch flame. If you need to adjust anything, use your titanium soldering pick or steel tweezers … NOT your fingers!

Quench (use steel tweezers to drop into a container of cool water).

Caution: Copper solder seems a bit more brittle than silver solder (I assume this is due to the phosphorous). So if you attempt to re-shape a solder join when hammering, you are likely to break the piece right at the join. Don’t worry — just re-solder it! Odds are, you won’t even need to add more solder. Just line it up nicely, wrap any beads with wet paper towel, position the broken join near you on the block, pull all the other parts as far to the back as possible, and re-heat the wire on both sides of the join. Wave the flame back and forth on the wire until the solder flows smoothly where you want it.

Note: Not all beads can tolerate tumbling or pickling, but most can tolerate both! If in doubt, test a single bead for the full amount of time before soldering a whole strand.

For basic information about copper solder, refer to previous Blog Post: I Love Copper Solder!

Both of these copper bracelets were tumble polished for about 2.5 hours:

Finished bracelet made of 6mm large-hole aventurine beads and 18-gauge copper wire.

Finished bracelet made of 8mm large-hole Fancy Jasper and 16-gauge copper wire. All links soldered with copper solder.

Tips for efficiently cutting wire with straight ends:

For an absolutely perfect cut, use a jewelers saw (do a quick search for tutorials on making your own jump rings). At the moment, I don’t have a good space for sawing, so here’s how to get good joins using flush cutters:

- Use a good pair of flush cutters, like these Lindstrom or Xuron flush cutters, and pay attention to the angle — hold the blades perpendicular (90 degrees) to the end of the wire.

- Do a few practice cuts. Notice that the outside of your cutters gives you a nice straight (flush) cut, and the piece of wire that was on the inside of the cutter blades has a “v” shape. If both sides of the cut have a “v” shape (see below), then they aren’t the right type of cutters, and it’s time to invest in a good new set.

- To cut matching links, trim off the “v” portion, then for the 2nd cut, position your cutters at the other end of the coil (or flat piece of wire, if you haven’t coiled it yet), so both ends of this new piece of wire will be flush (flat). This gives you a “v” on the spool end again, so keep repeating this process for perfectly matching links.

- If you forget, and the end of your new link receives a “v”, simply snip the “v” off and you now have a slightly shorter link — this is probably fine for a bracelet or necklace (or a design made of random-size links), but not so good for matching earrings.

Questions? I’m happy to answer them! ~Polly

10 Comments

Hi, I was wondering if this copper solder will take the Liver of Sulfur patina the same way that copper sheet does. Thanks! 🙂

Hi Ginger,

Yes, it does. I tested one of my bracelets just a moment ago with the Liver of Sulfur XL gel, and the whole thing antiqued nicely, solder joints and unsoldered portions.

That’s great! I’m going to order some right away! Thanks for testing it for me! 🙂

Thank you Polly for the great, brief instruction on copper soldering. I am new to wire work and your blog addressed my questions and then some.

I have to admit I was a little startled when I saw my name at the end of your article given I haven’t run across many women with this spelling.

Have a great day and thanks again! Polly 🙂

Hi Polly, I’m happy I answered your questions. And thanks for posting. Admittedly it does feel a bit odd to be addressing a note to Polly and signing it the same way! I don’t run across many either. ~Polly

Congratulations to you on this tutorial. It is the best I’ve come across on soldering copper. You touched on all details and I can’t wait to start on my copper bangle.

Aloha!

This is one of the best copper soldering, with a bead, tutorials I have seen. Thank you so much for sharing!

Thanks! This was a lot of fun. I should do it with sterling silver or fine silver sometime soon…

–Polly

Hi Polly, I love your blogs, so easy to understand for beginners. I finished my very first SS soldering class yesterday at the local Lapidiary club and so keen to try the copper. I love your design with gemstones. Just wondering what pickle can be used with gemstones or does pickle not affect gemstones whilst in pickle. Thanks for your inspiration. Jane

Hi Jane,

Thanks! Pickle affects some gemstones more than others. For example, it’s a terrible thing to do to pearls, but as long as you don’t leave them in very long, a lot of hard, non-porous gemstones aren’t too bothered by it. Pickle is very acidic, so if you have knowledge of the chemistry behind the gemstones you’re using, you might be able to predict how resistant they will be, to being affected by pickle. It also might be worth searching the ganoksin forum, or posing the question there. –Polly