Our original tutorial on “How to solder jewelry with Simply Swank Tools” has been very popular. Since the “Simply Swank” company no longer exists, I have attempted, here, to provide information on similar supplies, and to answer some questions.

About Soldering

Solder is a confusing topic. There are two completely different soldering methods used in jewelry making, yet people rarely explain which type they’re talking about – much the way people say they spent the weekend simply “at the lake.” (If they are your friends, you do know which lake … and hopefully this post will help you make friends with solder!)

Solder is a metal alloy that is melted to connect or coat metal pieces. Soldering is the act of melting and applying solder.

The two soldering methods are:

- Soldering with a torch. Often called hard soldering, brazing or silver soldering, although copper, brass, gold and other metals can be torch soldered. There are different grades of hard solder (which melt at different temperatures, and just to confuse things further, are called easy/soft, medium and hard). There are also different solder formulas to match the color of various metals. This post talks about copper wire solder, which is meant for torch soldering.

- Soldering with a soldering iron. This is often referred to as soft soldering, and is used with base metals (like pewter) and plated metals. This is actually ‘tinning”, which means adding a layer of solder to a metal base. The solder is made mostly of tin and has a (relatively) low melting temperature. Soft solder is pewter or silver colored. Never use a soldering iron with precious metal jewelry: it will ruin the jewelry.

Therefore, if jewelry is made of silver or gold, it has to be torch soldered. Successful soldering requires heating the metal pieces, not just melting the solder, so if the piece is very large or thick, it’s probably torch soldered as well.

First off, not all soldering irons are created equal. There are many varieties on the market and most were not designed for jewelry making. The two most important things to look for are tip style and wattage. We recommend a minimum of 60-watt soldering iron with a chisel tip. The pointy tip irons are designed for tiny electronics like circuit boards and are of little use for jewelry, other than sealing jump rings. Lower than 60 watts might not heat up enough. The 60w Hakko soldering iron meets both requirements! The 100 watt Choice Iron and Rheostat combination provides greater control over temperature.

Soldering iron tip comparison

The iron on the left has a pointy tip (not recommended). The iron on the right has the recommended chisel tip, but needs to be cleaned! Soldering is difficult when the tip is black and crusty. Try using the wet sponge to clean the heated iron or use the Hakko Superior-Quality 599B Soldering Iron Tip Cleaner.

Next, the solder itself. It is important to use lead-free solid-core solder. Avoid solders that have rosin or acid cores. Rings & Things sells Choice Solder and SILVERGLEEM Solder. All 3 work great with soldering irons; Staybrite is more expensive because of its higher silver content and included flux.

Third, flux. All solder requires flux in order to melt and flow. Novacan Liquid Flux and Stay-Clean Liquid Flux are both designed for use with soft solder. We recommend the flux be brushed onto the copper foil tape as you solder.

Here is a condensed version of the process:

Preparing to Solder a Glass Pendant

Prepare your work area. Remove extraneous (burnable or meltable) items from the immediate area. I like to use a cookie sheet with a Non-Stick Craft Sheet on top. The craft sheet allows for easy clean-up of the drips and spills of solder that will inevitably occur.

Copper tape creates the metal base needed for the solder to flow onto.

Sandwich images between 2 pieces of glass and wrap edges with copper foil tape, peeling off the tape as you go. If you plan to add a bail or jump ring, overlap the ends of the foil tape where you are adding the hardware. Fold the tape over from the edges to the front and back of the glass, being careful of the corners (think of it like wrapping a gift). Burnish smooth (a sharpie pen works well for burnishing). Clean with alcohol to remove any oils from your fingers – a clean surface is the best soldering surface!

Shaping the solder coil into a snake makes it easier to feed onto your soldering iron.

Prepare the Soldering Iron stand by adding a few tablespoons of water to the sponge in the reservoir.

If this is your first time using the iron, you will want to “tin” the tip the first time you heat it up and always maintain that layer of solder across the tip. By tinning the tip, you prevent the iron coating from oxidizing, which is a real problem when you have hot iron tips. Oxidation can corrode your tips forcing you to replace them more often, and the hotter your iron the faster they will oxidize. Tip tinning creates a layer of solder between the air and the iron, keeping oxygen at bay.

Plug in the soldering iron and allow it to heat up for a couple minutes. Touch the tip to the damp sponge. The iron is hot enough if the sponge steams a bit when you do this. Holding the solder in one hand and the iron in the other, briefly touch the solder to both sides of the tip. You may have to “rub” the solder onto the iron to start it flowing.

Now that your tip is properly tinned, you can start soldering. Try to solder immediately after tinning the tip, the sooner the better. Tinning improves conductivity and makes soldering easier, as well as quicker, which is a good thing. Periodically while you are working , (when the solder doesn’t seem to be flowing well), clean off any globs of solder on the sponge and re-tin the tip. Keeping the tip clean is important but constantly wiping it on a wet sponge will lower the iron temperature, and can cause early tip failure. Properly cleaned tips are bright and shiny.

Keep the iron in the stand whenever you are not actually soldering with it. Unplug the iron whenever you are working on another portion of the project for more than a few minutes. This is not only a good safety measure, but it will also extend the life of your soldering iron. When you are not using your soldering iron, you should keep a layer of solder on the tip, so before putting your iron in storage, apply a fresh layer of solder to the tip to prevent it from corroding. If you will not be using your iron for an extended period of time, you may want to store it (after it has fully cooled) in a zipper type bag to protect it further from corrosion and humidity.

Soldering a Glass Pendant

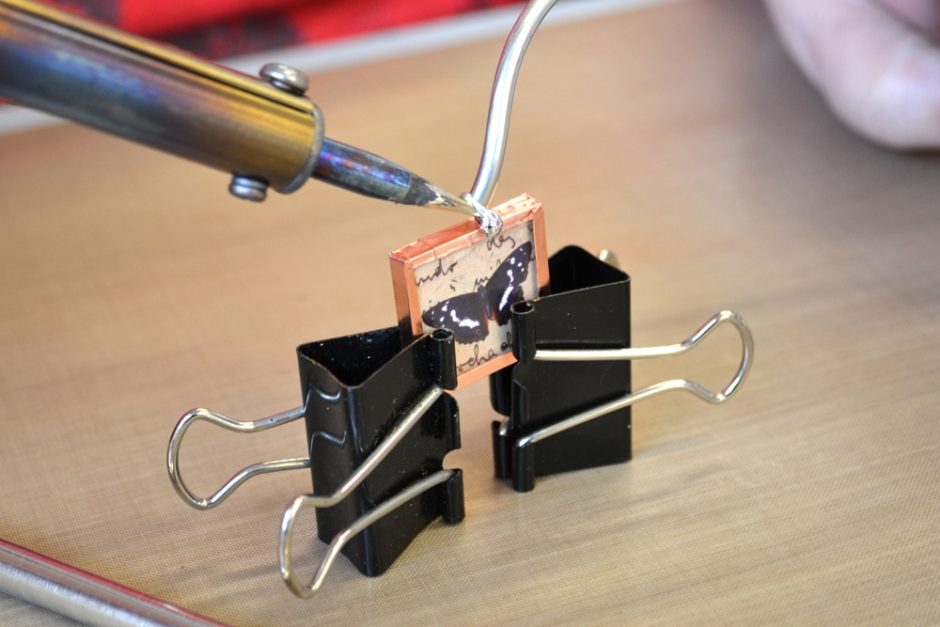

Apply flux to the copper tape. Touch your hot soldering iron to the solder to pick up a blob, and run the iron over the copper tape. Repeat. Repeat. (Some people melt the solder onto the tip of the iron and transfer it to the piece. I find I have more control by applying the solder directly from the roll to the tape.) Often you can pull the solder from the edges of the pieces to the front and back taped portions. Completely cover the copper tape with solder. If it looks lumpy, run the iron across the bumps to remelt the solder and smooth it out. Be sure to clean your soldering iron’s tip frequently. If the solder isn’t flowing, either the tip is dirty, your piece is dirty, you need more flux or you aren’t heating the piece sufficiently. Clips, clothespins or a third hand tool are all helpful tools for holding your piece while protecting your fingers.

The piece above is being held in place with binder clips, allowing me to hold the spool of solder in one hand, and the iron in the other.

Here I am holding a piece steady with bent chain nose pliers. Since flux can damage tools, and you may drip solder onto them, dedicate an inexpensive or already damaged pair for use in soldering.

Add a blob of solder to the point where you’d like to attach your jump ring. Apply flux to your jump ring. Use pliers or tweezers to hold the jump ring on the blob, and reheat the blob with the iron to secure it in place (watch out: the blob will melt quickly, and the jump ring will sink into it. Do not maintain the heat on the blob or the jump ring, or it will all melt together into a mess). Clean off any extra flux with window cleaner or rubbing alcohol, file rough edges, buff with a polishing cloth, and you’re done!

Making soldered pendants is totally addictive. Microscope slide glass is an affordable way to indulge your pendant-making habit.

The Rings & Things Exclusive Glass Soldering Jewelry Making Kit provides all the basics for you to start out with a new skill. Just provide your own images, scissors, water, and work surface, and you are ready to go.

So, DIY and make some unique and meaningful collage pendants of your own!

~ Rita

Hint: If you love the soldered piece, but don’t like the bright and shiny finish, Novocan Patina will darken the solder covered parts.

Edited January 2022 to update links.

52 Comments

This is an excellent “how to” explanation. Thank you so much.

All I want to do is solder jump rings closed. What products do you recommend I purchase?

Hi Joan,

It depends on what metal the jump rings are.

If they are plated, then you need a soldering iron, soft solder, and flux. Any of the ones listed in the article will work fine.

If they are sterling silver, then there are a few more factors to consider – please describe the material of the jump rings, and what stones or other materials might be near them, and how close they are to the jump rings.

Hi, Polly,

To follow on this question, I want to solder sterling, vermeil, fine silver, gold-filled and maybe 14k gold jump rings.

I’m working mostly with a wide range of semiprecious stone beads, as well as some crystals and glass.

I don’t plan to do any other metalwork at this time, and although I am trained in it, we didn’t do anything with jump rings or stones, and I really don’t want to get into a whole regular soldering setup. I just want to be sure my jump rings on the pieces I’m making don’t come open or catch on anything.

Any recommendations you might have would be very welcome. I did buy a soldering iron intending to use it for this purpose, but now I’m concerned.

Hi Wendy,

I don’t recommend using soft solder (i.e., a soldering iron) with precious metals.

Soft solder can ruin sterling silver (which means also vermeil and fine silver). It doesn’t ruin it when you soft solder it … the potential problem is far in the future if anyone attempts to SILVER-solder the piece in the future.

Gold-fill is very difficult to solder, but not impossible. You need a very delicate touch. (Personally I have not attempted it — but most gold fill jump rings are fairly strong, so it’s usually not needed.)

Soft solder is also not the right color for vermeil, GF or 14kt yellow gold.

Try this page for a bit more explanation between the various types of solder, and the melting temperatures and tools required.

http://www.rings-things.com/Learn/Soldering-101/

It will give you a better overview than I can in this brief reply box. =)

Overall, I really recommend using the type of solder that matches your material (soft solder and an iron for silver-colored basemetal, copper solder and a torch for copper, silver solder and a torch for sterling/fine silver, and gold solder — with a higher-powered torch — for gold). Unfortunately, there is no soft solder (yet) for gold-tone basemetal jewelry.

To avoid soldering, yet still get more security, uou might want to try using slightly thicker jump rings, oval jump rings, 2 jump rings, or split rings instead.

~Polly

Hi…I want to melt a little dent in pewter pebbbles to put in a swarovski crystal. Can I use a soldering iron to do that? Can I do that with silver too? Also which soldering iron do I purchase? Btw, love your tutorial! Thank you so much!

I think you can, but it would be hard to control the size and shape, and you might melt a lot more than you want to. When you bring it to a melting temperature, it becomes liquid … and liquids like to flow flat or follow the hot soldering iron, not stay poked down. You would have better luck pulling them upward where they can “freeze” as a point (think photos of Lake Michigan’s iced-over waves during a Chicago winter). So I think you’d be better off using a wide centerpunch or some type of grinder to get your dimple.

For soft solder, you can use one of the soft soldering irons in this article. For hard (silver solder), you need a torch of some type. We sell micro torches (much like a creme brulee torch) that operate on butane, the same thing you fill a zippo cigarette lighter with.

Hello! I loved this tutorial. I want to make a pendant like the one in the tutorial, but plan to encapsulate a beetle in it instead of paper 🙂

The pendant will have to be much thicker. Would you do anything differently or do you have any suggestions for tackling this project?

Thank you!

Hi Elisabeth,

You might want to use the glass bezels instead of the microscope slides:

https://www.rings-things.com/Products/Glass-Bezel-Cups-and-Tiles/ or these hinged glass pendants:

https://www.rings-things.com/Products/Hinged-Frame-Pendants/

Here are a few articles that give some how-to ideas:

https://blog.rings-things.com/?s=glass+pendant

I have been seeing necklaces all over and would love to make some for Christmas. I am about to purchase the soldering kit, but it doesn’t look like jump rings are included in the kit. Which ones do you recommend?

Thank you very much!

Elizabeth.

Hi Elizabeth,

I recommend the assorted jump rings, so you’ll have sizes that work for any diameter chain, cord, etc that you may want to use them with: https://shop.rings-things.com/cart/pc/Jump-Ring-Round-Assorted-Sizes-p20649.htm

~Polly

I have created digital art files with a lot of detail. I do not think these details would show up well on1 square inch small areas.

.

1) Do you know if there 2 inch or larger glass covers comparable to the 1 inch microscope slides of this technique?

2) Would it be possible to perform the solder edging process using ordinary small window paned sized glass? I suspect that the small window panes would need non-soldered supports, for example, display stands or some kind of clamps for suspension displays.

Thank you from an ordinary person rather than a professional.

Signing Visual Art as In-Wonder

Hi In-Wonder,

We do have 3×1″ and 2×2″ slides @

https://www.rings-things.com/Products/Memory-Glass-and-Microscope-Slides/

And I’m going to let someone more knowledgeable about soldering glass, answer question #2.

I know how to solder the glass, but I want to add a wire design on top of the glass. How can I do that?

Thanks,

Leigh

Hello: found your great site quite by accident and you have given me ideas with materials that I had right in front of me ex. microscope slides and the art of sandwiching. Thank you.

Your instructions are easy to understand and helpful!

Are there other things I can use soft solder on? I`m not real crazy about the pendants, even though I have lots of them. I want to see other things I can do. Seashells with jump rings for one. Thanks!!

Hi Linda, As long as the item in question will hold up to the heat of soldering and can be taped with the copper foil tape, this style of soft soldering can be done to it. I don’t have any examples to show here, but in-house, we have wrapped and soldered gemstone beads, flattened marbles, glass bezels, etc. ~ Rita

Hi Polly

Really helpful post, thanks!

Can you clarify which type of file you use, to file rough edges, please?

I also find it tricky to soft solder my jump rings to my oval domed pendants. Not sure if my soldering tip is too thick, but I really want to get a subtle amount of solder on the jump ring, to secure it to the pendant. Also awkward trying to use the third hand, as it won’t hold the pendant [too deep].

Any tips?!

Many thanks…

Helen

Hi Helen,

Polly asked me to offer some advice.

To remove large lumps from the solder, you can either reheat with your soldering iron (be sure to use flux) or use a fine metal file:

#69-252-01-4 EURO TOOL Flat File, 6″, #4 Cut

You will need to be careful not to scratch the glass.

You can also smooth small imperfections with 3M sanding sponges:

#69-257-0005 3M Sanding Sponges, 1200-1500 Grit

#69-257-0004 3M Sanding Sponges, 800-1000 Grit

When soldering on jump rings, a smaller tip is desirable; 1/4″ will work well. Try angling the soldering iron so you are using the chiseled corner and not the entire flat surface of the tip.

For safely holding pieces in place while soldering, we like using folder clips from the office supply store. They are available in a variety of sizes, so one should work for your size of glass. Here is an in-use image:

http://www.rings-things.com/blog/wp-content/uploads/2013/04/adding-solder.jpg

I hope this helps!

Mollie Valente

Rings & Things Design Team

Hi, I wanted to know which jump rings would be ok to use with the Rings & Things soft soldering kit?

Hi Cody, I suggest either the white plated or silver plated jump rings. Both are available in a variety of sizes, as well as an assortment bag if you aren’t sure what sizes will work best for your projects. ~Polly

Hello! This post and comments are so helpful!

If the necklace chain to accompany the pendant was going to be sterling silver, am I correct that you would use a torch and silver hard solder?

Will the silver solder ever tarnish or discolor? Will it last as long and match the color of the sterling silver?

Thank you so much!!

Hi Michelle,

I wouldn’t solder glass pendants with a torch – your glass might shatter, and most things (like paper) that you sandwich between the panes of glass, will burn.

Sterling silver, including the silver solder for soldering sterling and fine silver, definitely tarnishes (oxidizes).

Soft solder – some of these tarnish quickly, and some are very tarnish resistant. It also depends on how clean you keep your work. If you use excess flux, your work will often yellow or blacken quickly, so if you use a solder that requires flux, use only what you need, or clean the piece thoroughly when done.

Sometimes you want it to “tarnish” (oxidize), to give it an antique look, or bring out the differences between high points and low points. In this case, you want to use something like Novacan Patina, and avoid solders that promise anti-tarnish qualities.

My favorites that we carry are the SILVERGLEEM soft solder and StayBrite. (StayBrite is best if you have a variety of small projects; SILVERGLEEM is definitely my choice for soldering glass pendants.)

~Polly

I would like to create the pendants you have shown above with the memory glass and the microscope slides. What size copper foil do I need to use 1/4″? or 5/16″? to cover and sandwich the glass slide together? Thank you so much for this great tutorial and question and answer forum!

Nansea

Hi Nansea,

Thank you for your interest in our blog post on soldered glass pendants. This is one of my favorite techniques for creating personalized jewelry.

The microscope slides are 1mm thick, so a sandwich of “glass/image/glass” will be slightly thicker than 2mm. The choice of foil width is partially subjective; I prefer the narrower 1/4″-wide foil. The 1/4″ converts to 6.35mm, and will result in a 2mm-wide foil frame on the front and back side of the glass piece. If you prefer a wider frame, use the 5/16″-wide foil; 5/16″ is equal to 7.94mm.

Mollie

Do you still offer the glass solder kit? I can’t find it in your store. If not, can you list the individual items I would need to get started. Thanks!

Hi!

Yes, we do: https://www.rings-things.com/Products/Soldering-Irons-and-Tools-for-Soft-Solder-Jewelry/

As of 12/29/2015, it’s out of stock, but I believe it will be back in stock soon.

~Polly

I have recently picked up my iron again to make some pendants. After finished it almost looks like there is moisture inside next to the pictures. What am I doing wrong? I am using microscope slide glass. Any help would be appreciated!

Nancy

Hi Nancy,

It could simply be that last time you did this, the weather was dryer, and in March the air might be damper. I will ask around and see if there are ways to avoid the moisture appearing inside (aside from having a humidity-controlled environment to work in).

-Polly

I would like to know the best way to solder crystals on bottles. I have been doing crosses but there has to be an easier way of doing this.

Thanks,

Tina

Hi Tina,

Do you have a picture of what you’re trying to do? And what method(s) have you been trying? We haven’t soldered crystals onto bottles, but if we know what you’ve tried that hasn’t worked, we might be able to offer some good suggestions.

– Polly and Mollie

Hi Polly and Mollie,

I finally found this site again. I have a photo but do not know how to post it to this site. I am still having issues. I use the copper foil method but the joints are just not strong enough.

Thanks,

Tina

Hi, fantastic tutorial! Can you please tell me what product to use to change the solder from a silver color to a brassy/gold color once the soldering has been completed (if that’s possible?). I’d like my pendants to have the same look as the ones in the final “Microscope Slide Pendants” picture of this tutorial. Thank you!

Hi Vanessa,

That photo has some issues. There is a little discoloration on the frames, that needs to be cleaned, and this gives a kind of dark brassy hint of color.

But mostly I think that photo needs to be color corrected — they don’t look nearly that brassy in reality. I’m afraid there isn’t a gold or brass colored low-temp solder, or a good way to give the silver solder a (permanent) gold color.

~Polly

I just started working with a soldering iron and glass in making wind chimes. I’ve been having trouble in keeping the jump rings on them until I came across your webpage. Thank you for the VERY helpful idea of first putting a blob of solder and then melting it while gently pushing the jump ring into it. I really appreciate you taking the time and patience to explain it to us ‘newbies’.

Hi, and thank you for a great tutorial.

Could you tell me why I have to stay away from rosin core solder wire ? I thought it sounds great to not have to use flux…..but I know nothing about this.

Monica

Hi Monica,

If you google “what is rosin core solder” you’ll see that it’s usually 40% lead (Lead is often listed as Pb). So if you have old rosin-core solder sitting around that was purchased in years past, it is likely high in lead content. If you have new rosin-core solder that says it is lead free, give it a try. ~~Polly

Thank you for the answer 🙂

I have been soldering glass/crystal chandelier prisms together to make crosses but the joints are just not strong enough. I use the copper foil method. Any suggestions?

Thanks!

Hi Tina,

You might try wire wrapping the crystals together first, and make sure all the wobbles are eliminated before you apply the foil. Then cover your wire wrap with the copper foil and solder.

Copper foil with a layer of solder over it works fine for 2 flat sheets of glass, but isn’t tough enough to hold items together that are trying to come apart.

–Polly

[…] followed this tutorial for soldering glass pendants. It’s so helpful. My glass items would still be broke without […]

I have been having the same issue as mentioned above with it looking like moisture gets in when I solder my pendants. I am very careful to make sure everything is dry and clean and I live in the desert so not humid here. Did you find any reason why this is might be happening? Could the iron be too hot? It’s very frustrating and sad…

It is maybe too much flux? In your desert situation, I can’t think of anything else that might be causing the moisture!

The flux may be creeping in under the edges of the copper. The heat of soldering may be pushing it there, so try applying less flux and perhaps not *quite* to the edges of the copper (it will probably creep itself to the edge anyhow, so stopping a little short with your brush should still get you complete coverage).

~Polly

Thanks for your quick response. I will try using a bit less flux and see how it does.

First, thank you for this tutorial.

I recently broke out my soldering iron for the first time in six or seven years. Truth told, I’d take two classes before and never done any soldering at home. I’m having trouble with the copper tape sticking. I make sure the surface is clean and dry, and I burnish until my hand cramps. I even bought new tape, thinking that my old tape had “gone bad.” In addition, the tape wanting to lift is making for sharp edges. None of my class pieces from years ago have this problem. Do you have any suggestions? I’ve scoured the internet for answers and have come up empty handed.

I aprreciare your help!

Hi Stephanie,

Old adhesive can quit being sticky, especially in extra humid, extra hot, or freezing environments so that was a good idea. But since you are still running into the same problem, I think you might actually be over-burnishing it. I’ve over-worked other types of metal projects and added curves where I didn’t want them. Try another one but don’t try too hard … just do a quick gentle burnishing, and go extra easy on the fold line. Also, I’ll ask our resident glass expert in case she has ideas.

–Polly

Thanks, Polly.

I bought some more fresh adhesive from your site and tried to burnish with a light touch. The tape is still lifting up. The only thing I can think of at this point is that my soldering iron is getting too hot. (I don’t have a rheostat.)

Could that be the problem. If so, what is the correct temperature setting for soldering?

Thanks! Steph

Hi Stephanie,

A few thoughts on the copper foil tape not sticking:

After cleaning the glass, go over the edge with isopropyl alcohol (rubbing alcohol); this is a degreaser and dries almost instantly.

When applying the copper foil, your hands need to be clean and free of grease or lotion.

I like to use the handle of a “Sharpie” pen to burnish the foil to the glass. The foil tape needs to be sealed to the glass or the flux will work its way underneath during soldering and compromise the adhesive.

And a few tips on soldering:

Don’t over solder and let the project get too hot. Too much heat will make the tape adhesive gummy and the foil will start to lift from the glass (and then the flux gets under the foil and compromises the adhesive). If you need to touch up the soldering, allow the whole project to cool and then start again.

The best soldering temperature for a tin-based solder ranges from 600 °F to 800 °F. Jewelry projects are small, so the lower end of that temperature range is usually best.

The sponge that comes with Item #69-419 “Choice, Cast Iron Soldering Stand” not only helps keep the soldering iron tip clean, but will also cool the soldering iron tip temporarily.

http://www.rings-things.com/Products/Soldering-Irons-and-Tools-for-Soft-Solder-Jewelry/Choice-trade-Cast-Iron-Soldering-Stand.html

Let me know if any of the suggestions here are helpful–or if you need further assistance.

Mollie Valente

Rings & Things Customer Service/Designer

Help! Using iron to solder copper tape to sea glass. EVERY time half to tape comes up with the solder as I work. If I need to cut a piece to fill in a curve on an unusll place on glass it peels up as I work. I clean well and is completely dry. And if tape overlaps it peels.

New tape.

Hi Mary,

It is super frustrating trying to solder pieced together copper foil! Even if you have followed all the helpful hints from my reply dated “February 21, 2018 at 3:39 pm”, you will still probably have some problems. Not piecing together is best, but in those instances where the foil splits on an inward curve it is necessary. Here are a few suggestions:

*Use a larger piece of copper foil to fill the gap, and be sure to overlap and burnish it to the first layer of copperfoil.

*Use as little flux as possible to start with (the flux gets underneath the foil and compromises the adhesive).

*Try to gently drop a bead of solder over the places the foil overlaps to seal the edges and prevent the piece from lifting off.

*Don’t overheat/over-solder the area (heat and liquid solder will cause the copperfoil filler piece to lift).

I hope this helps!

Mollie Valente

Rings & Things Customer Service/Designer

I use a little magnet to hold the ring

it better then a plier

jack 47 71